About Us

Welcome to CNCRepair

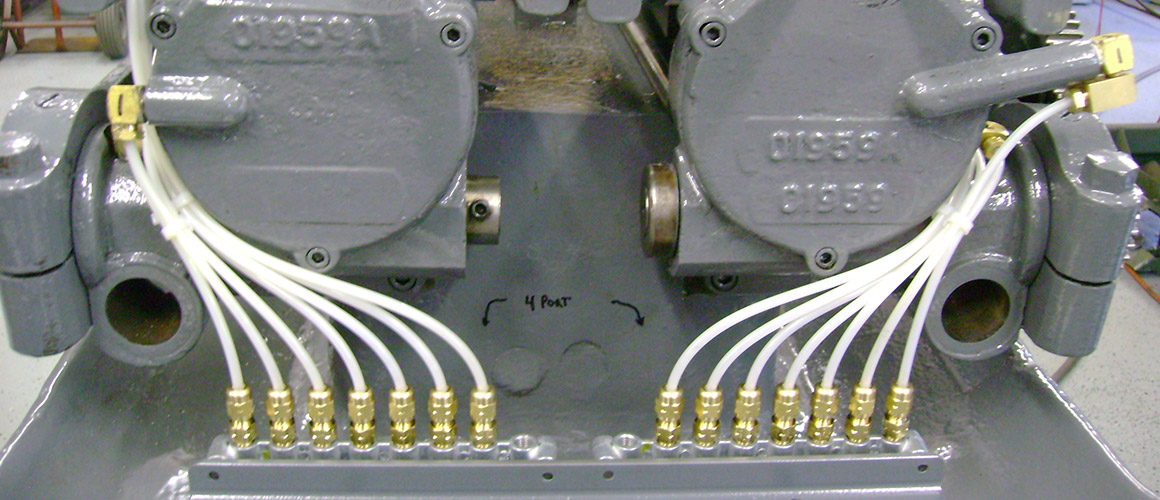

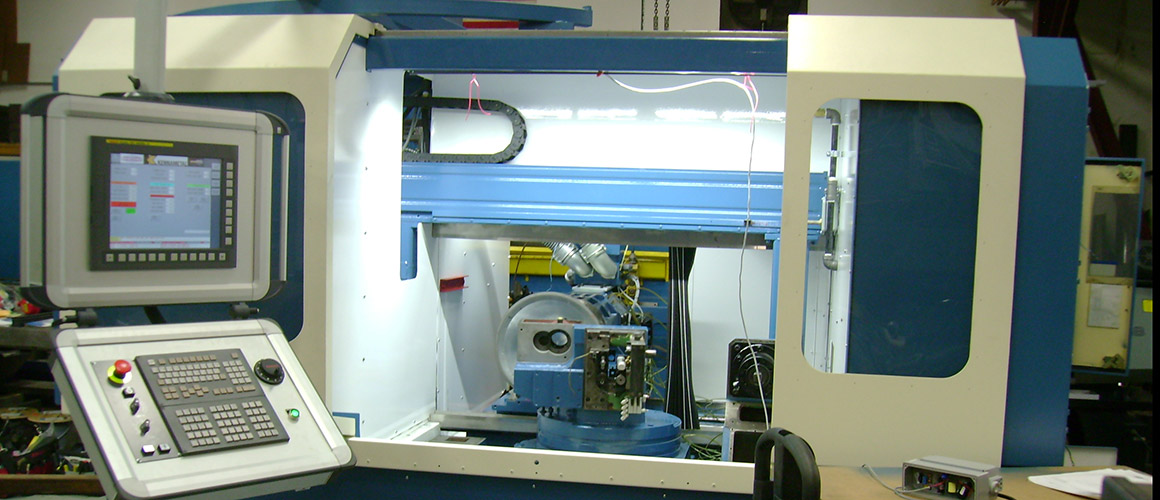

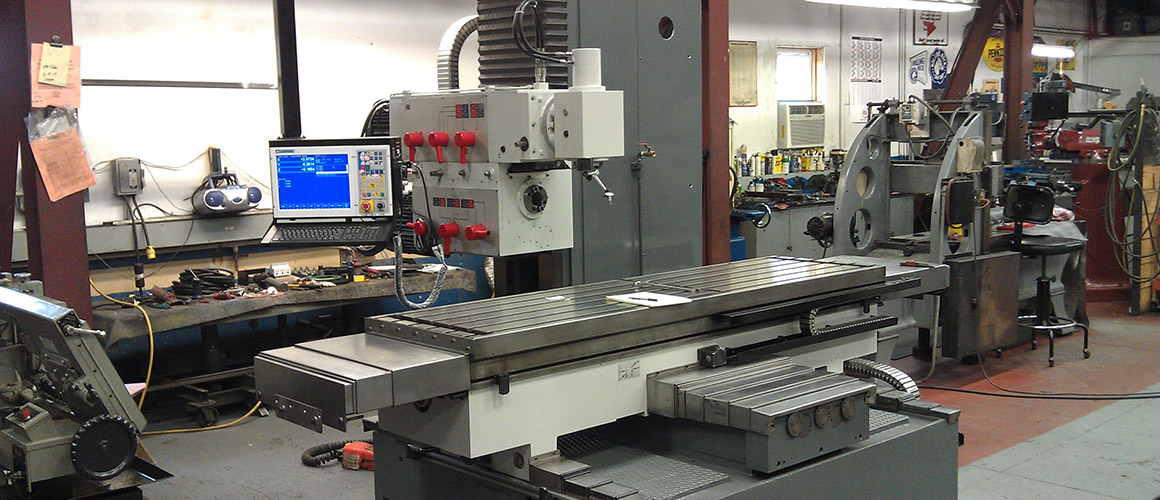

We provide the South Africa area with prompt, reliable & knowledgeable service, offering troubleshooting & repairs of industrial machinery throughout the South Africa Region. We specialize in CNC machinery! For us no job is too big or too small. Our highly-skilled professionals are trained to provide you with the solutions you need as well as the quality you deserve. We have made a strong presence in our business market and are continuously striving to offer the best to our clients, something you will quickly realize when you choose us. We know that you will find what you are looking for with us because we stand behind our work and know that we will deliver the satisfaction that you need. If you are in need of someone to provide reputable troubleshoot and repair or provide preventative maintenance for your machinery, we are your company. In need of training on your machinery? We can help you there too. We work on everything regarding CNC Machines!